Corrosion is the gradual destruction of a metal material through chemical reactions with its environment. It occurs when metals are exposed to moisture, oxygen, acids, and other chemicals.

It can cause the metal to become weaker and less durable over time, leading to structural failure, loss of functionality, and decreased aesthetic appeal. Some common examples of corrosion include rusting of iron and steel, tarnishing of silver, and pitting of aluminum.

To prevent metal rusting, various protective measures can be taken such as using anti-corrosion coatings, applying sacrificial anodes, and regular maintenance and inspection.

What is Anti-Corrosion Paint?

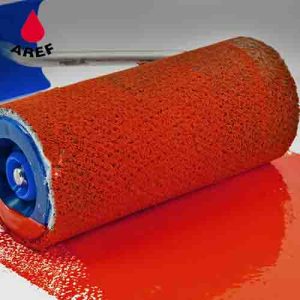

Anti-rust or anti-corrosion paint, also known as rust-inhibiting or corrosion-resistant paint, is a type of coating that is designed to protect metal surfaces from rust and corrosion.

It contains chemicals that actively prevent the formation of rust by creating a barrier between the metal and the environment.

It can be applied to a wide range of metal surfaces, including steel, iron, and aluminum, and can help extend the useful life of machinery, vehicles, and other metal objects.

How Does Anti-Rust Prevent Metal Corrosion?

Anti-rust paint works by creating a barrier between the metal surface and its environment. The paint contains corrosion inhibitors such as zinc, which helps prevent the metal from corroding by blocking air and moisture from reaching the metal surface.

The paint also forms a protective film over the metal which provides a physical barrier to prevent water and air from accessing the metal. This film can also bond chemically to the metal surface, preventing the metal from further oxidation and rusting.

In summary, anti-rust paint works by creating a barrier between the metal surface and moisture, air, acids, and other corrosive elements in the environment.

Advantages of Anti-Rust Paint:

The advantages of using anti-rust coatings, such as anti-rust paints, include:

-

Corrosion protection:

The primary advantage of using anti-rust coatings is the protection they provide against corrosion. They create a physical barrier that prevents moisture, oxygen, and other chemicals from coming into contact with the metal surface, preventing or slowing down the corrosion process.

-

Durability:

Anti-rust coatings are specially formulated to withstand harsh environments, making them durable and long-lasting. This means that they can provide protection against corrosion for extended periods of time.

-

Aesthetic appeal:

Anti-rust coatings come in a variety of colors and finishes, allowing you to choose an option that best suits your needs. This can help enhance the aesthetic appeal of your metal surfaces while also protecting them from corrosion.

-

Cost-effective:

Using anti-rust coatings can be cost-effective compared to other methods of protecting metal from corrosion, such as replacing or repairing corroded parts.

-

Versatility:

Anti-rust coatings can be used on a wide range of metallic surfaces, including steel, iron, aluminum, and copper, making them a versatile solution for protecting metal parts and components.

Disadvantages of Anti-Rust Paint:

While anti-rust coatings have various advantages, there are also some potential disadvantages to keep in mind. These may include:

-

Limited protection:

Anti-rust coatings are not always 100% effective and may provide limited protection against severe corrosion or exposure to corrosive environments.

-

Cost:

High-quality anti-rust coatings can be expensive, especially when used on large or complex structures.

-

Time-consuming:

Applying anti-rust coatings can be a time-consuming process and may require multiple layers and careful preparation of the metal surface.

-

Toxicity:

Some anti-rust coatings may contain toxic chemicals, which can pose a risk to human health and the environment if not handled and disposed of properly.

-

Maintenance:

Anti-rust coatings require regular maintenance to ensure their continued effectiveness and protection against rust and corrosion over the long term.

Differences in Anti-Rust and Paint:

The main difference between anti-rust coatings and regular paint is their intended purpose. Anti-rust coatings contain active chemicals that are specifically designed to prevent rust and corrosion of metal surfaces.

Regular paint, on the other hand, is primarily used for aesthetic purposes, such as improving the appearance of a surface, adding color or gloss, or protecting the surface from environmental factors like UV radiation, moisture, and heat.

Anti-rust coatings are a type of paint that is formulated with special corrosion inhibitors to protect metal surfaces from rust and corrosion. So technically speaking, anti-rust coatings are a type of specialized paint.

Anti-Rust Types:

There are several different types of anti-rust coatings, each with its own unique characteristics and advantages:

-

Zinc Coatings:

These coatings provide excellent protection against corrosion and are commonly used in industrial applications.

-

Epoxy Coatings:

Epoxy coatings are known for their durability and resistance to chemicals, making them ideal for use in harsh environments.

-

Polyurethane Coatings:

These coatings are often used in marine and offshore applications, as they provide excellent resistance to saltwater and other harsh conditions.

-

Acrylic Coatings:

Acrylic coatings are often used on outdoor surfaces such as fences and metal roofs, as they provide good resistance to UV light and weather.

-

Oil-based Coatings:

These coatings are often used in automotive applications, as they provide good rust protection and can be easily applied with a brush or spray gun.

Leave us a comment and express your opinion about this article. We look forward to your views and comments.

Contact us for free advice on anti-corrosion and other chemical products such as paints and primers, adhesives, pigment pastes, and raw materials.

Our colleagues will answer you as soon as possible.

Follow Aref Chemical’s page on Instagram.

17 Responses

Great job. Full information and useful for anti corrosion types. thanks

Itís difficult to find knowledgeable people for this subject, however, you seem like you know what youíre talking about! Thanks

How long does the anti-corrosion paint extend the life of the metal?

So useful thanks

https://arefchemical.ir/

good

https://daroosf.com/%D9%85%DA%A9%D9%85%D9%84-%D8%A2%D9%87%D9%86/

very important

https://daroosf.com/%DA%A9%D9%85%D8%A8%D9%88%D8%AF-%D9%85%D9%88%D8%A7%D8%AF-%D9%85%D8%B9%D8%AF%D9%86%DB%8C/

thank you

https://behdama.com/

thanks

https://tavatranslation.com/%da%a9%d8%a7%d8%b1-%d8%af%d8%b1-%d9%81%d8%b1%d8%a7%d9%86%d8%b3%d9%87/

really important

https://behdama.com/%da%af%db%8c%d8%ac-%d9%81%d8%b4%d8%a7%d8%b1/

danke schone

https://daroosf.com/%D8%A7%D8%B3%D8%AA%D8%B1%D8%B3/

exactly

https://daroosf.com/%D9%85%DA%A9%D9%85%D9%84-%D8%A7%D9%86%D8%B1%DA%98%DB%8C-%D8%B2%D8%A7/

true

https://tavatranslation.com/%da%a9%d8%a7%d8%b1-%d8%af%d8%b1-%d9%81%d8%b1%d8%a7%d9%86%d8%b3%d9%87/

really useful

https://arefchemical.ir/%d8%a7%d9%86%d9%88%d8%a7%d8%b9-%d8%b1%d9%86%da%af-%d8%b3%d8%a7%d8%ae%d8%aa%d9%85%d8%a7%d9%86%db%8c/

👌👌👌

👍👍

✅✅✅

Thanks excellent